I like to use traditional joinery methods in the construction of the small timber frames that I build. Utilising the English tying joint, which has been in use since at least the 17th century, to allow the connection of the top plates and tie beams all to happen in one corner. It relies on 2 mortise and tenons on a Jowl post along with a dovetailed lap joint. Its a shame such a beautiful piece of joinery can’t be seen once its all put together!

Timber framing has always been a fascination of mine since I was a child. It shows off the intricacy of furniture making, in regards to cutting tight joinery, but on a much larger scale. I am constantly inspired by the work I see other more advanced timber framers doing and I try and push myself further into it every time I get the chance to build something like this. Its really one of the most enjoyable types of work I do.

In part 2 there will be a large decking structure heading out into the woods and also verandas coming of each side of the roof.

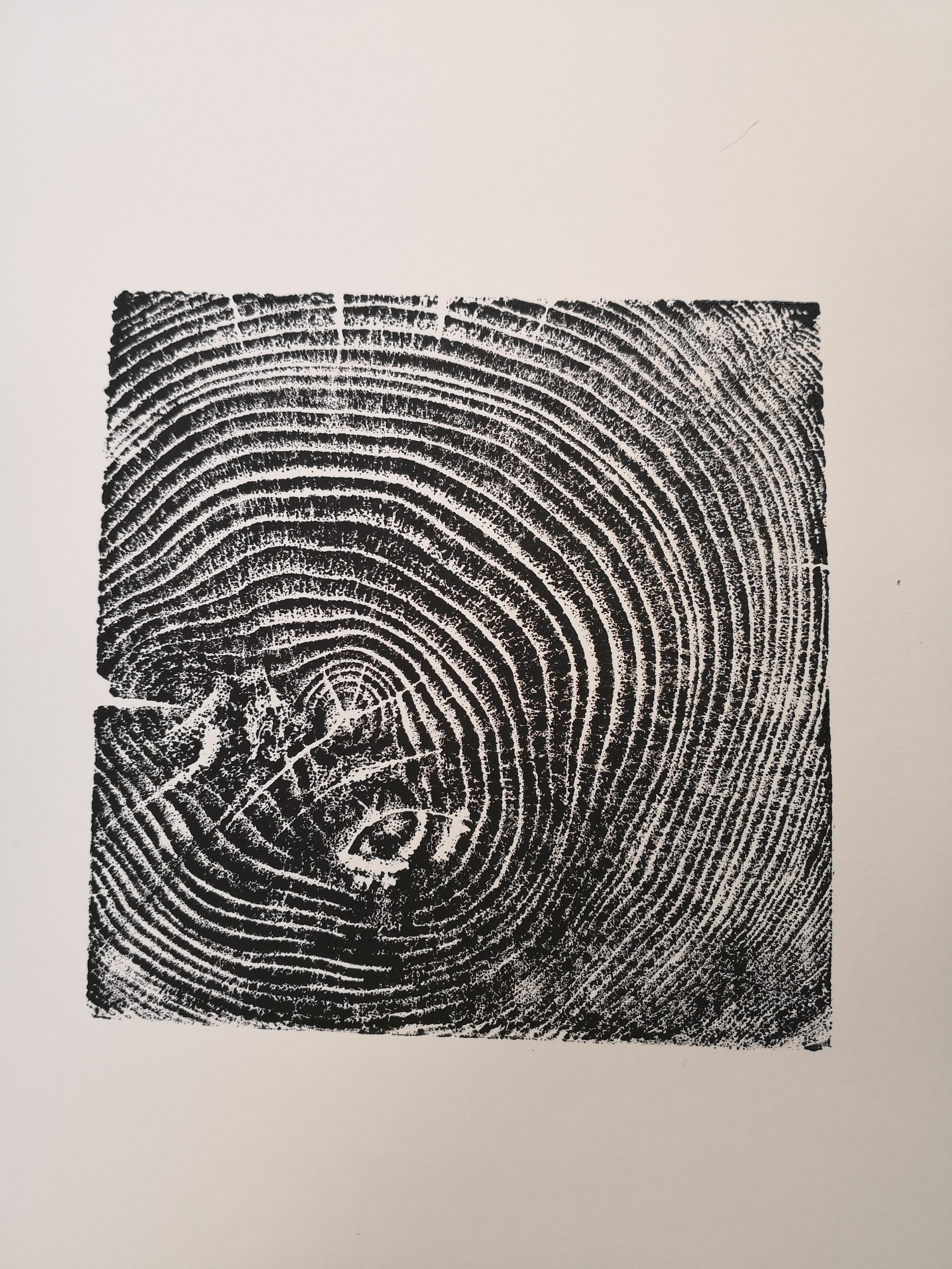

An opportunity came up to salvage a trailer load of good quality cypress logs from a woodland renaturalisation project happening in Heathfield and undertaken by my colleague and good friend Harry Aspinall (www.arvoresarb.com) . All the trees had grown up in a forest setting so were clear of large knots low down in the stems and had at least 6m of straight timber. We saved the best of the logs from the biomass pile.

At the same time I was organising a timber framing job in Plaistow for a client with a very environmentally orientated design specification. Most types of cypress are durable outdoors, strong and also quite attractive looking timbers. Its a shame that we have such an obsession with oak framing in the UK when there are many more options available to us that don’t have to be sent across from questionable sources in European countries. Of course Oak is a wonderful timber and this building will be laid out on a mixture of oak and sweet chestnut framework but all sourced within a 40 mile radius of the project.

The joints are held together with oak pegs. The holes in the tenons are slightly off set away from the shoulders of the tenons to allow the peg to pull it tighter into the joint. This means as the wood dries out the joint will remain tight.

6 concrete pads were put into the ground to allow the oak and sweet chestnut framework to be elevated slightly off the ground. I milled the oak from a tree removal job in forest row. The sweet chestnut came from some coppice in Lamberhurst. Both of these timbers are really durable due to their high tannin content and also very strong which is why I opted to use them for the base.

A lapped dovetail joint in the central truss/rafter tie.